Infrastructure

Our facility is fully air conditioned (BMS controlled) and the manufacturing processes are fully automated for temperature, humidity control, sanitization and eliminating risk of microbial contamination.

We employ the Kathabar System – a world leader in industrial humidity control, which ensures superior capsules quality and low microbial presence. The system aids in Clean in Process (CIP) system, which is controlled by PLC, provides excellent sanitization of the melter mixer for gelatin preparation.

The vessel interiors are steam cleaned with the help of fully automized cleaning process control sequentially programmed cycle, followed by hot purified water spray. This sanitization process is in compliance with the international cGMP norms for microbiological tests.

Machinery and Capacity

- Processes pneumatic drives, programmable logic controls and dedicated drives.

- Two stage locking feature for increased filling efficiency.

- Completely automated manufacturing process for minimal human interaction.

- Camless dipping over conventional dipping for better capsule profile

- All controls displayed on PLC for better process control, leading to consistent quality.

- Single Machine Single Room (SMSR) with separate HVAC for regulatory market.

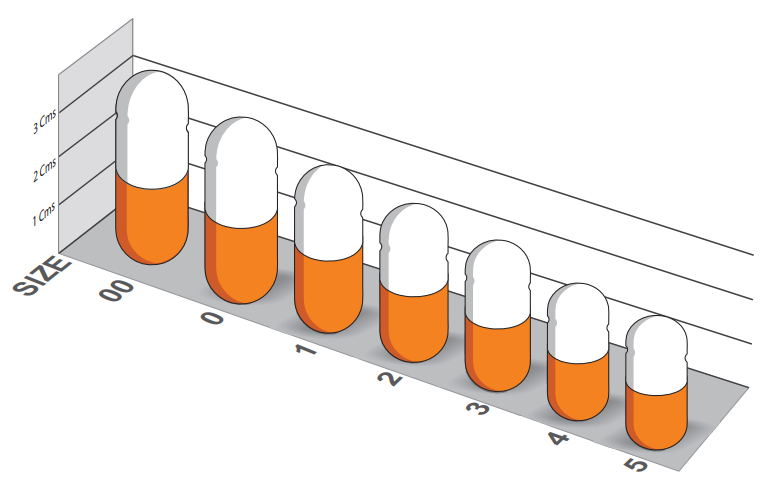

| Size | Quality (Pieces) Per Month |

|---|---|

| 00 | 45 Million |

| 0 | 200 Million |

| 1 | 45 Million |

| 2 | 225 Million |

| 3 | 100 Million |

| 4 | 50 Million |

Size 0EL and 5 are under development.

Printing and Sorting Facility

Dinesh Remedies has installed high speed printing machines capable of printing on capsules as per the customized requirements of our clients. We provide printing in several varieties such as

- Single & Double Color Axial and Circular Printing

- 360 Degrees Oriental Printing

- Metallic Printing Facility

In addition to this, Dinesh Remedies has also installed imported automatic sorting machines capable of sorting all critical, major and minor defects in all capsules. Machines are also capable of removing any printing defect to provide capsules of the highest quality.

Packaging

Depending on mode of transport and duration, we offer the following types of packaging to fulfill our customer’s needs:

Standard Pack:

Capsules are initially put in an LLD polyethylene bag, which is further packed in a 5 ply corrugated box that is complying with all types of pharmacopeias.

Special Pack:

Capsules are put in an LLD polyethylene bag, which is further packed in a 5 ply corrugated box containing 5mm Styrofoam sheet on every side to protect capsules from temperature variation.

Complete Pack:

To give best protection, capsules are packed in an aluminum bag, which is stuffed in a 22mm EPS box. Furthermore, this is sealed in a 5ply corrugated box for maximum protection.

NOTE

- According to customer requirement, LLD polyethylene bag can be replaced with an aluminum bag for additional protection.

- Quantities & box sizes might differ as per the total order quantity, mode of shipment & temperature-humidity condition.

Products

Industry